Technology

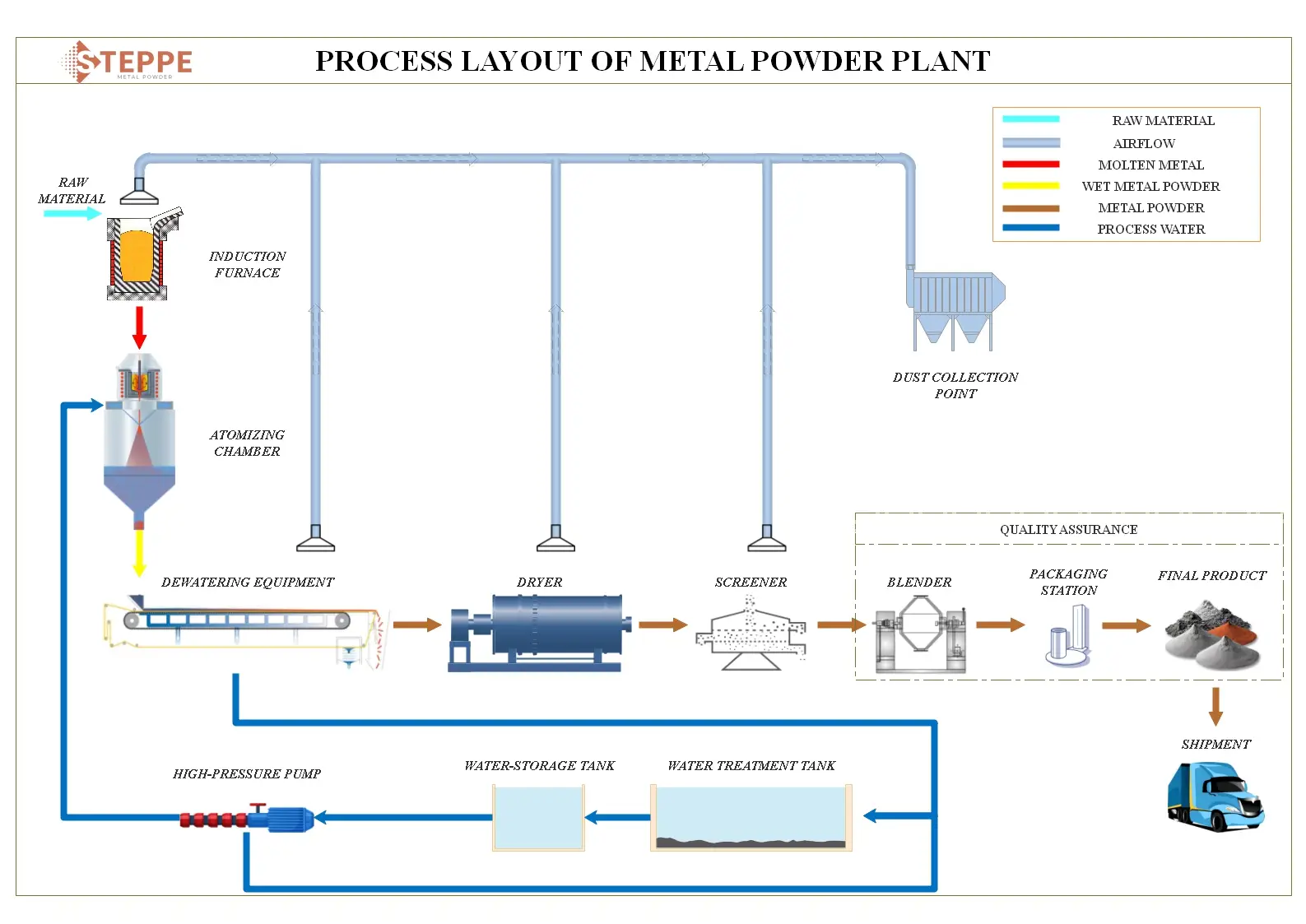

Production Process

Quality and control testing

Water atomization process

Atomization is the most commonly used process to commercially produce metal powders due to its high feed to yield ratio. The high-pressure water atomization procedure has proven to be a viable, low-cost process to achieve fine particle size distributions for iron, stainless steel, and low-alloy metal powders. The economic savings and pre-alloying capabilities provide this technique desirable advantages over competing methods and technologies. This field has advanced to remove many of the shortcomings relative to powder characteristics, i.e. irregular particle shape, lower tap densities, and oxidized surfaces, that have hindered the industry and it now closely resembles gas atomized powder properties.

In principle, the water atomization process is applicable to all metals that can be melted, but is commercially used for the production of iron, copper, alloy steels, brass, bronze and low-melting-point metals such as aluminum, tin, lead, zinc, and cadmium. The process involves a stream of molten metal impinged by jets of water, which then breaks up into droplets that rapidly freeze to form granules (> 1 mm) or powder (> 1 mm), depending on the composition of the metal and the water pressure. Traditional granulation uses pressure in the range of 2 – 5 bars (200 – 500 kPa) and typically produces granules in the range of 1 – 10 mm. Due to low pumping costs, very large flow rates can be accommodated.

To make finer powders, higher water pressure is needed (the median size of the granules are inversely correlated with pressure), thus it is necessary to use more controlled streams, typically from a tundish arrangement instead of a launder as in many granulators. To run more modest flow rates, we typically use nozzles from 3 mm to 30 mm in diameter to provide a flow rate from 5 kg/min to approximately 500 kg/min. Water pressure at around 20 bars produce coarser powders with a median size of 0.3 mm while water pressure at 200 bars produce finer powder with a median size of around 50 μm. Drying requires significant energy, thus increases costs, but may be done if, for instance, a smelter is selling to a refiner.